SUBARU’s Idea for a Digital Transformation Strategy

SUBARU’s Idea for a Digital Transformation Strategy

The automotive industry is undergoing a once-in-a-century upheaval that adds further complexity to car-making. Until now, automakers were tasked with the product planning, development, and manufacture of cars which were then distributed to dealerships. More recently, however, it has become possible to secure touchpoints with customers through the use of data and digital technologies.

It is generally said that consumer needs are shifting from goods to experiences. Subaru provides products that have functional value backed by sound car-making and considers it important to strengthen relationships with customers through their experiences driving our cars. Subaru’s DX strategy utilizes data and digital technology to strengthen Mono-zukuri (car-making) while simultaneously facilitating the creation of experiences.

Our Common Goal is Strengthening Ties between SUBARU and our Customers

For a smaller car manufacturer like Subaru to respond to the current upheaval in the automotive industry, we need to select and establish focuses in regard to the use of data and digital technology. As a result of these major changes, the vertical division of units by function (such as development, procurement, manufacturing, sales, and after-sales service) that worked well for car-making in the past is becoming obsolete. In response, we are changing the way business is conducted across the entire Company by establishing data systems and enabling everyone to share that data to facilitate changes to organizational culture in the future.

Subaru has many customers around the world wishing to enrich their lives by leading a lifestyle that includes a car. In response to these customers, we are working to establish data and digital-based “experience-making” for our customers as our new challenge. We are also working to enhance the value Subaru provides to customers in the form of Enjoyment and Peace of Mind by strengthening our Mono-zukuri as described previously. Our common goal is to increase the number of customers who feel an affinity with our value statement, and deepen our relationships with these customers. In other words, the ultimate goal of all our initiatives is to deliver happiness to our customers.

Strengthening Mono-zukuri Using Data and Digital Technology

We have identified three major issues related to the development and production of cars.

The first is “process”. Until now, we repeated a cycle where we designed parts, made prototypes, assembled those parts into a prototype for a single vehicle, and then evaluated it. However, this cycle is no longer sufficient to keep up with current development processes as they become more advanced and complex. We aim to streamline this process by using a digital twin that combines partial model-based development using data and digital technology in conjunction with real-world development.

The second is “operations”. The number of variations in models and power units, such as hybrids and BEVs1, is increasing. This, in turn, has increased the number of items that need to be managed by each department involved in Mono-zukuri. It is easy for these departments to focus on management as their goal, even though the original purpose of management was to make improvements. We need to promote a renewed focus on improvement activities that need to be done. To do so, it is important to establish data handling tools and skills to process a large number of control items and expand their use on-site.

For example, some manufacturing sites are implementing initiatives to use BI2 tools. Until now, manufacturing processes included the creation of paper records on-site. These records were then entered into a computer manually. We have changed this system to enable direct input into a tablet. Vehicle numbers, images, and records are input into a tablet on-site, and that data is managed in an integrated way. This has increased the speed at which supervisors can monitor and respond to trends, and the information linked to a single car can now be shared by the manufacturing site with various departments, such as production engineering, quality control, and development, in a timely manner.

- *1: BEV: Battery electric vehicle

- *2: Business Intelligence (BI): Software that can assist with management and work tasks by analyzing and visualizing a range of data maintained by the company

The third is “organization”. The conventional structure for car manufacturing uses an organization with vertical, function-based divisions, such as for development, procurement, manufacturing, sales, and after-sales service, with development being handled as projects involving all divisions. Dividing the organization by function is very effective in terms of allowing own-process completion for individual processes. However, it is no longer suitable for new trends involving concurrent activities with external organizations and new business models such as connected services. In addition, each department and operation exists as an individual silo, making it difficult to share data across departments.

We believe that building a conventional integrated system under current conditions would not only require tremendous resources, it would also mean that we end up facing the same issues again when new business models appear. Rather than integrate the system, we opted to integrate data by building a company-wide data integration platform that shares data across departments and further advances Mono-zukuri.

One such initiative is Global Product Lifecycle Management (PLM). This system manages all information about each car, from development and production to after-sales maintenance. This makes it possible to understand the health condition of the car and allows us to promptly notify existing owners in the unlikely event of a problem with a model in the same series during the production stage. By facilitating access to data tracking the lifetime of each vehicle, we are working to provide more convenience and create new experience value for the customer.

Fostering DX Human Resources

Currently, Subaru is proactively hiring mid-career DX human resources, but as a basic principle, we believe it is critical to foster human resources internally in this area as a company engaged in Monozukuri. As an example of this, we have launched the Software Human Resource Development Project for engineers as a way to adapt to electrification (see page 42 of this report). In addition, we have been focusing on on-site education in cooperation between a specialized IT department and the respective operating department. Furthermore, we are working to build a system to raise awareness and skill levels on the manufacturing floor, utilizing data and digital technologies. To do this, we have taken a standard training program for data scientists, one of the six kinds of DX human resources defined by the IPA3, and adapted it to suit the Subaru ideals. This course is used to train experts who can use data as a tool for improving work on the manufacturing floor. To ensure the establishment of individual skill development as part of our corporate culture, we are conducting a continuing chain of grassroots activities in which the first generation of students mentors the second generation, and the second generation then mentors the third generation.

*3:Information-technology Promotion Agency (IPA), Japan

My role is to support the production of molds for car body parts from the IT technology side. The molds I work with are used with presses to shape sheet materials such as steel and aluminum into panel parts such as bonnets and doors, which are important to a car’s external appearance. This is why I work to develop systems to ensure that the machine tools used to make the molds operate within tolerances measured in units of a hundredth of a millimeter. We have always had quite a bit of data in our engagements with mold and panel manufacturing floors, and I thought that being able to make better use of this data would streamline operations and enable the provision of higher quality molds. And, since this would consequently improve mass-produced panel quality and deliver happiness to our customers, I joined the data scientist training program.

Participants in this training program came from many different departments. In addition to general classroom lectures and practical training, there was also a lot of time for discussion and sharing the data utilization issues we had been facing in our respective departments. Hearing opinions from colleagues in other departments where I normally have no work connection was refreshing. It offered me new insights and hints for formulating improvement plans in my own department. I was also able to turn the lessons I learned in this training program into action, developing and proposing a plan to use data for improving press line quality.

Tatsuya Ichikawa

Vehicle Body Manufacturing Engineering Department

After completing the program, I also became an instructor to help train the next class of trainees. Part of this is my strong feeling that it is more effective when employees who have a real sense of Subaru’s situation today provide guidance to their internal colleagues. It is my desire to motivate colleagues who are aware of issues but have not been able to take action, and I would like to expand the circle of my support to help make Subaru as a whole even better.

Creation of New Value by Enhancing Experience-Making

Nowadays, customers connect to the outside world through their smartphones, and their cars are equally as connected. We hope that by creating these connections, people will enjoy new experiences that come from the enjoyment of driving, made possible by the enduring safety that Subaru provides as a functional value. We want to create a cycle where these new experiences make customers appreciate their Subaru, and also make them want to buy a Subaru as their next car as well. We are striving to create new value through facilitating experiences that strengthen our ties with the customer through the use of data and digital technology.

Our connected service has already started in the U.S. and has been well received by customers who can use their smartphones to start their engine remotely and operate the air conditioner. There are also vehicle-linked services such as a locator that shows where the driver has parked their car in large parking lots at shopping malls, etc. In addition to this, related features for reserving a visit to the dealership and displaying vehicle information are already being used by many customers. Connected services in Japan started with the Levorg, which went on sale in 2020, and we are currently thinking about enhancing functionality and expanding the market in the future.

-

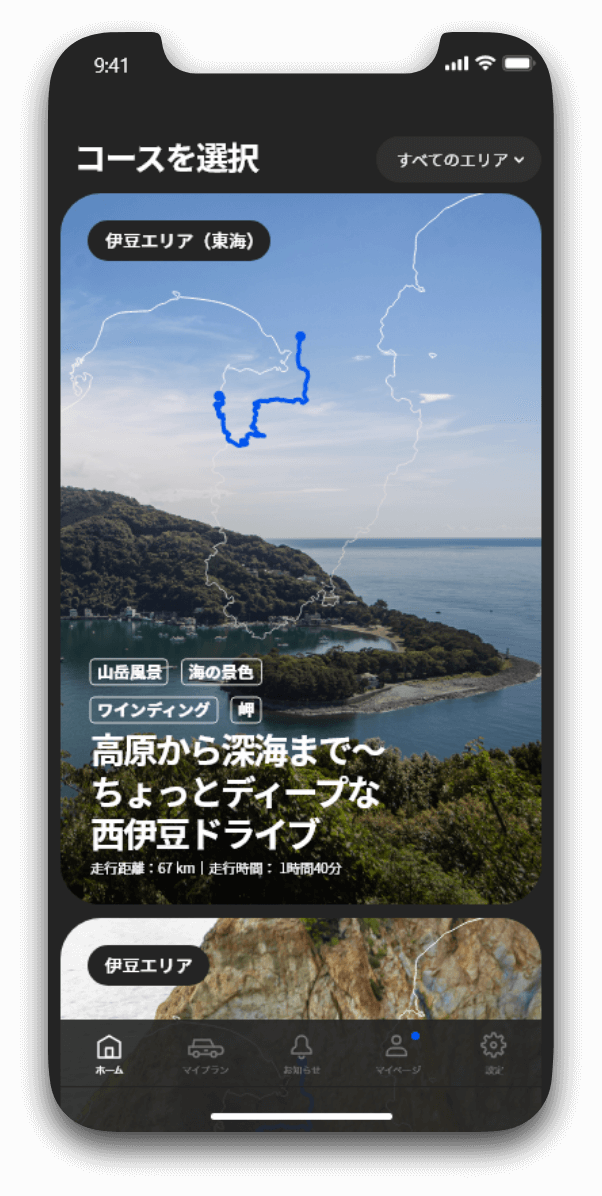

We also started the Subaru Digital Innovation Lab to make use of digital technology and data in areas such as digital marketing, sales and more. Studies and analysis conducted at this lab revealed these characteristics Subaru at a glance’s customers: they consider their car to be more than just a means of transportation; they demand value that goes beyond mobility; and they seek an emotional element that cannot be expressed in terms of efficiency. Our customers tell us that they sometimes intentionally take a longer route to their destination, or that they do not always follow the route given by their navigation system. We see this feedback as an example of our customers experiencing the features of Subaru vehicles that appeal to their senses, and this leads to feelings of excitement and affinity. We created the SUBAROAD driving app to offer this kind of experience to as many customers as possible. The concept of the app is to present the route that provides the most driving pleasure in their Subaru vehicle, rather than the most efficient route, and it is already being used by many of our customers.

We are using data and digital technology to enhance Subaru’s approach to car making, and we are also creating new experiences, using a range of customer contact points, to allow our customers to have enjoyable experiences in their Subaru vehicle. We consider both of these initiatives to be the same goal, which is to strengthen the ties between the Subaru brand and our customers.

We hope that all of our customers will be looking forward to Subaru’s unique DX initiatives in the near future.