Prevention of Pollution

Our Approach

To realize an enjoyable and sustainable society as well as sustaining its own business activities, the SUBARU Group considers it essential to prevent the pollution of public water resources, soil, and the atmosphere. The Group endeavors to accurately measure its environmental impact and reduce it to a minimum by making the best use of its environmental management system.

Management System

SUBARU, in cooperation with relevant departments and staff involved with environmental laws and regulations at domestic Group companies, utilizes its environmental management system and works to prevent and minimize their materialization of environmental risks involved in its business activities (environmental accidents, pollution, noncompliance with laws and regulations, etc.).

Among the specific measures taken across the SUBARU Group are enhanced sharing of information on environmental laws and regulations through creation of a network of officers in charge of this area within the SUBARU Group; provision of training in environmental laws and regulations to these officers; and review of the procedures and practice of internal audit relating to compliance with environmental laws and regulations. In implementing these initiatives, we will emulate the PDCA cycle of the environmental management system, identifying issues in each fiscal year as the basis for improvement in the next, thus taking continuous action to ensure comprehensive compliance with environmental laws and regulations.

SUBARU is also collaborating with suppliers from the design and development stages of next-generation vehicles in reducing the use of environmentally hazardous substances in automobiles, including cleaner exhaust gas and reducing volatile organic chemicals (VOCs) in vehicle interiors.

Reducing Environmentally Hazardous Substances in Products

SUBARU is actively working to reduce environmentally hazardous substances in its vehicles, working in cooperation with its suppliers from the design and development stages of its next-generation vehicles. We maintain achievement of the environmentally hazardous substance reduction targets for lead, mercury, hexavalent chromium, and cadmium set by Japan Automobile Manufacturers Association, Inc. (JAMA) for all new models released in and after 2008. Furthermore, in order to ensure compliance with the REACH regulation, ELV Directive, the U.S. Toxic Substances Control Act, Japan's Chemical Substance Control Law, and other regulations enforced across the world, we are further reducing the use of lead and replacing hazardous chemical substances in flame retardants, UV absorbers, and other materials with alternatives.

Cleaner Exhaust Gas

To achieve and maintain clean air across the globe, SUBARU is developing technologies for cleaner exhaust gas, targeting not only conventional air pollutants such as hydrocarbon compounds and nitrogen oxides but also particulate matter, which is feared to have serious impacts on human health. At the product level, we are expanding our range of models that meet the latest regulations by country, while addressing emerging regulations at the development level.

- Japan: 2018 low emissions standards

- U.S.: State of California’s SULEV standards

- Europe: Euro 6 emission standards (final stage)

- China: China 6 emission standards

We will develop and propose reasonable products for customers based on the results of research conducted to identify the optimal specifications in each country, including research on the components of exhaust gas that will be regulated in the future. To this end, we are designing materials on an atomic level to improve the performance of the catalyst, which plays a major role in producing cleaner exhaust gas, while also reducing the use of precious metals.

Reducing VOCs*1 in Vehicle Interiors

SUBARU is reviewing the components and adhesive agents used in vehicle interiors in order to reduce the use of volatile organic compounds (VOCs) in this area.

For the Legacy, Levorg, Impreza, Forester, and SUBARU BRZ, we achieved the voluntary target set by JAMA*2 by reducing the concentration of the 13 substances defined by the Japanese Ministry of Health, Labour and Welfare to levels below the indoor concentration guideline values (as revised in January 2019). We will continue our efforts to reduce the levels of VOCs to make the in-vehicle environment even more comfortable.

- *1

- Organic compounds that easily volatilize at room temperature, such as formaldehyde and toluene, which are said to cause nose and throat irritation.

- *2

- Voluntary target set by JAMA in its “Voluntary Approach in Reducing Cabin VOC Concentration Levels,” which was announced with the intention of reducing the in-vehicle concentrations of the 13 substances designated by the Ministry of Health, Labour and Welfare to levels equivalent to or lower than the values set in the guidelines, for new models produced and sold in Japan in and after FYE March 2008. We will satisfy the revised indoor concentration guideline values by the Ministry of Health, Labour and Welfare for all new vehicles launched on or after 2022.

JAMA’s “Voluntary Approach in Reducing Cabin VOC Concentration Levels” (Japanese version only)

Environmental Compliance at SUBARU Sites

In addition to complying with environmental laws and regulations, SUBARU has set its own voluntary environmental standard values, which are 20% stricter than the regulatory values set by law. We are committed to never exceeding the regulatory and voluntary thresholds and striving to achieve the goal of zero environmental complaints and zero environmental accidents. In FYE March 2024, there were one air-related and two water quality-related violations of statutory standards, and one water quality-related and one noise-related violation of voluntary standards at the Gunma Plant, and one water quality-related violation of statutory standards at the Utsunomiya Plant. At the Tokyo Office, there were two water quality-related violations of statutory standards and four water quality-related violations of voluntary standards. We are conducting a root cause analysis of these issues, including investigating drainage systems and facilities, and will explore and implement measures to rectify the situation.

| Name of the Site | Number of Cases |

|---|---|

| Tokyo Office | 6 |

| Gunma Plant | 5 |

| Utsunomiya Plant | 1 |

One noise-related violation of voluntary standards occurred at Subaru Logistics Co., Ltd. We intend to identify the cause of this and work to prevent recurrence.

FYE March 2024 Environmental Performance Data for Plants and Offices

Environmental Accidents

We are committed to achieving the goal of zero accidents, both on-site and off-site. In FYE March 2024, there were six incidents of emissions into the environment, and seven incidents of emissions on-site. Five of these on-site emissions occurred at the Gunma Plant, and we are working to identify the cause and take measures to prevent recurrence. With regard to incidents at the Tokyo Office, we are conducting a root cause analysis, including investigating necessary water discharge amounts and water inflow, and will explore and implement measures to rectify the situation.

| Name of the Site | Number of Cases |

|---|---|

| Gunma Plant | On-site incidents 5 Off-site incidents 3 |

| Utsunomiya Plant | On-site incidents 1 Off-site incidents 1 |

| Tokyo Office | Off-site incidents 2 |

| Head Office | Off-site incidents 1 |

As for Group companies in Japan, there was one off-site incident at Fuji Machinery Co., Ltd. As with our compliance with environmental laws, regulations, and ordinances, we will work to prevent recurrence.

Environmental Complaints

We are committed to achieving the goal of zero environmental complaints, but in FYE March 2024 we received two. We intend to prevent recurrence by uncovering the causes of the complaints.

| Name of the Site | Number of Cases |

|---|---|

| Gunma Plant | 2 |

Noise, Vibration, and Offensive Odors

The Gunma Plant conducts daily patrols premised on the fact that people and measuring instruments respond to odors and noise very differently, and we are continuing our efforts to improve production facilities, among others.

Soil and Groundwater

We started our voluntary soil and groundwater tests at our locations in 1998 and have since implemented purification measures and groundwater monitoring as required. Since the Soil Contamination Countermeasures Act came into effect in 2003, we have also filed reports and conducted tests in accordance with the law.

PCB Waste

SUBARU is auditing and treating polychlorinated biphenyl (PCB) waste as planned. We are currently conducting a final survey of the status of PCB waste treatment at each SUBARU base and at Group companies and Dealership in Japan, and the SUBARU Group plans to complete the disposal of PCB waste by FYE March 2028.

Hazardous Waste

SUBARU has had no significant spillage, nor has it transported waste deemed hazardous under the terms of Annex I, II, III, and IV of the Basel Convention*.

- *

- International treaty on the control of movements of hazardous wastes between nations and their disposal procedures.

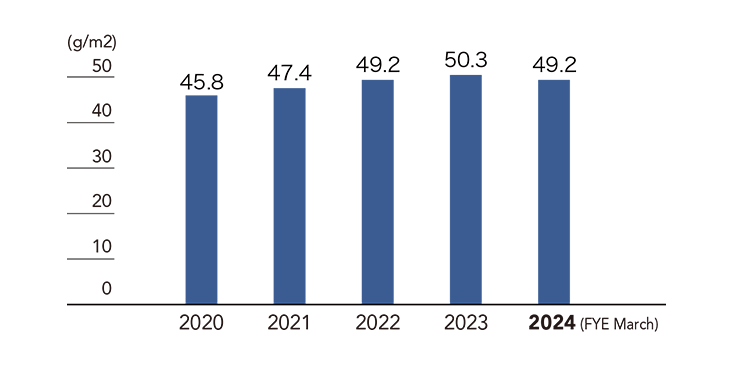

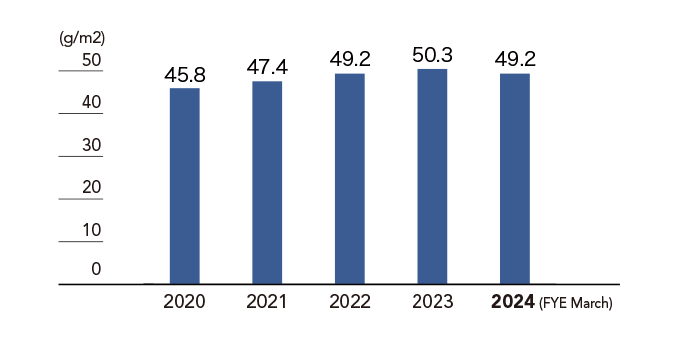

VOC

SUBARU manages volatile organic compounds (VOCs) emissions during the automobile painting process using an emissions per unit coating area calculation method. We are reducing the amount of cleaning thinner used in the automobile painting process and increasing recovery to reduce VOC emissions during painting. FYE March 2024 emissions decreased 2.2% compared with the previous fiscal year to 49.2g/m2.

VOC Emissions During the Automobile Painting Process

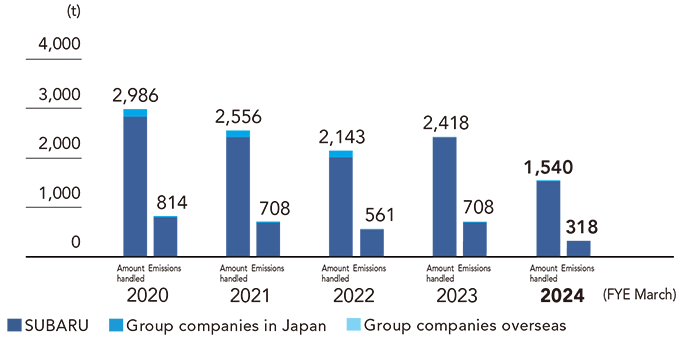

Chemical Substances Regulated by Japan’s Pollutant Release and Transfer Register (PRTR) Act

Scope

- SUBARU:

- Gunma Plant, Tokyo Office, Utsunomiya Plant, Handa Plant, Handa West Plant

- Domestic Group companies:

- Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Industrial Co., Ltd., Subaru Logistics Co., Ltd.

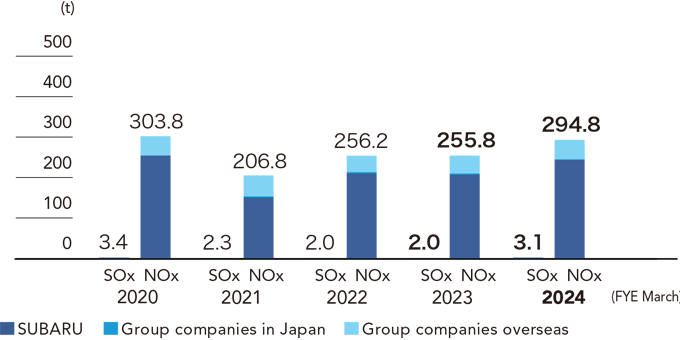

NOx and SOx Emissions

Scope

- SUBARU:

- Gunma Plant, Tokyo Office, Utsunomiya Plant, Handa Plant, Handa West Plant

- Domestic Group companies:

- Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Industrial Co., Ltd., Subaru Logistics Co., Ltd.

- Overseas Group company:

- Subaru of Indiana Automotive, Inc.