Mitigating Climate Change

- Our Approach

- Management System

- Risks and Opportunities Identified

- Strategy

- Risk Management

- Medium- to Long-term Goals (Long-term Vision and Milestones)

- Initiatives

- Life-cycle Assessment

- Product Initiatives

- Site Initiatives

- Sales Initiatives

- Logistics Initiatives

- Procurement Initiatives

- Other Climate Change Initiatives

- (Carbon Pricing)

- (External Partnerships)

Our Approach

SUBARU recognizes that climate change is one of the most pressing global issues. Toward its target of achieving carbon neutrality by 2050, SUBARU will reduce CO2 emissions from its products, factories, and offices to help decarbonize society. Accordingly, it has set long-term goals, and is working to achieve them with medium-term goals as intermediate milestones.

In addition, we believe that battery electric vehicles (BEVs) will eventually become a mainstay driver of carbon neutrality from a medium- to long-term perspective. As the environment surrounding electrification continues to change drastically, and with difficulties foreseeing the future, SUBARU will continue to focus on the development of BEVs from 2025 to 2026, which is positioned as the early stage of the transition to BEVs, while keeping a close eye on the trends in regulations and the market. We are taking various actions based on the recognition that it is extremely important to ensure flexibility and expandability, using this concept to adapt to such changes flexibly and to scale at once when the direction of the shift becomes clear.

Management System

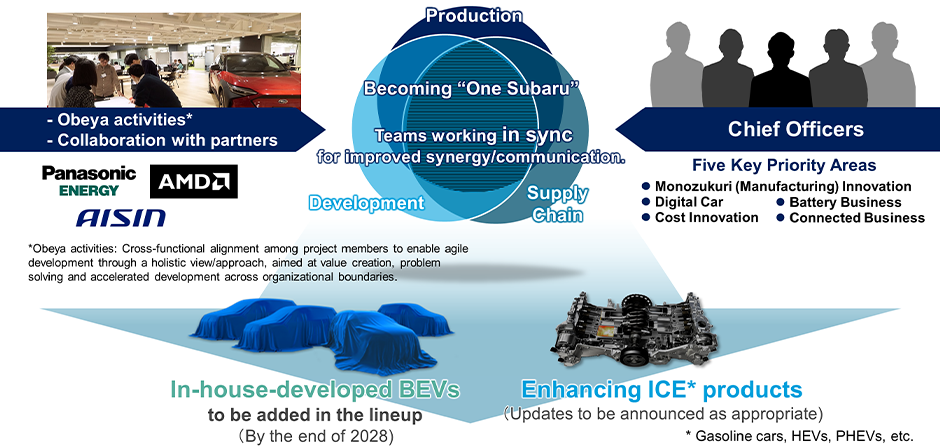

Recently, the business environment has been experiencing disruptive and non-linear changes at an unprecedented pace. In response to these major changes in the external environment, under our new organizational and officer system, we aim to accelerate "Monozukuri Innovation" and "Value Creation" as stated in the New Management Policies. Furthermore, by strengthening Company-wide cross-organizational functions, clarifying executive responsibility, and establishing a system to bring our policies to fruition, we aim to accelerate our efforts to address the core priority themes and achieve overall optimization.

Established Five New CXO (Chief X Officer) Positions in the Automotive Business Unit

SUBARU has newly established five Chief Officers (CXOs) who will be responsible for its five core priority themes: "Monozukuri Innovation," "battery business," "digital car," "connected business," and "cost innovation." These officers are engaged in cross-departmental action to break down departmental barriers, restructure the organization, and accelerate our "Monozukuri Innovation" and "Value Creation."

| CXO (Chief X Officer) | Mission |

|---|---|

| CMzO: Chief Monozukuri Officer | Lead efforts to halve the development process and lead time, halve the configuration and number of parts, and halve the production process and lead time. Drive initiatives to achieve world-leading "Monozukuri Innovation" |

| CBBO: Chief Battery Business Officer | Lead the overall advancement of the battery business, including ensuring stable procurement, competitiveness, and business viability |

| CDCO: Chief Digital Car Officer | Drive initiatives to achieve world-leading "Value Creation" through the digitalization of automobiles |

| CCBO: Chief Connected Business Officer | Drive initiatives to achieve world-leading "Value Creation," primarily in the "out-car" domain |

| CCIO: Chief Cost Innovation Officer | Lead and oversee Company-wide efforts to achieve cost competitiveness |

Reorganizing and strengthening the organization and functions related to "Monozukuri Innovation" and "Value Creation"

In order to reorganize and strengthen the organization and functions related to "Monozukuri Innovation" and "Value Creation," SUBARU has established the Value Strategy Office within the Corporate Planning Division to enhance the product portfolio strategy function. Furthermore, we have renamed the Product & Portfolio Planning Division to the Product Business Division to engage in ICE*-specialized (including hybrids) planning and development to maintain and improve product competitiveness, as well as to improve after-sales product competitiveness and promote planning for "Retaining Value" initiatives, etc.

- *

- Internal combustion (e.g., gasoline) engines

Climate Change-related Governance Harnessing our Environmental Management System

SUBARU has established the Environment Committee for the purpose of promoting the sustainable growth of both society and the Company, and thereby contributing to global environment conservation. The committee discusses targets and measures from broad as well as medium- to long-term perspectives that accommodate environmental standards required by future societies, and evaluates the progress of related implementations and achievements.

The Environment Committee is chaired by the Executive Officer in charge of the Sustainability Division appointed by the Board of Directors. Details of discussions by the Environment Committee are reported to the Sustainability Committee. We also have a system for escalation and reporting to the Executive Management Board Meeting and Board of Directors to be used as necessary. Management of climate change-related activities is included in the responsibilities of the environmental management structure. Environmental risks and opportunities associated with climate change are assessed and monitored, and undergo management review. Then, particularly critical proposals are deliberated and decided at the Board of Directors. Each of the five bodies within the structure—Production & Environment Subcommittee, Global Warming Prevention Working Group, Domestic Affiliated Companies’ Environment Subcommittee, Sales and Service Environment Subcommittee, and Logistics Environment Subcommittee—meet twice a year for the purpose of monitoring.

Governance Structure for Climate Change

Climate Change Governance in the Entire Life Cycle

In order to contribute to the realization of a decarbonized society through the reduction of CO2 emissions throughout the life cycle of our business activities, SUBARU holds monthly CN Promotion Meetings, bringing together departments representing the five areas of “product use,” “materials and components,” “transportation,” “disposal,” and “manufacturing.” In these CN Promotion Meetings, members from each area worked together and shared information, formulated a master plan from a medium- to long-term perspective, and took actions to visualize and mitigate emissions in each area in the interest of achieving carbon neutrality by 2050. SUBARU operates cross-company forums whose aim is CO2 reduction over the entire life cycle and whose activities are subject to the overall supervision of the Environment Committee as part of carbon neutrality initiatives.

Risks and Opportunities Identified

SUBARU defines and identifies risks and opportunities associated with climate change to achieve sustainable business activities.

We have identified a number of risks associated with climate change. Initiatives to address climate change may be inadequate or abnormal weather may cause delays in procurement, production, and distribution. In addition, transition risks and physical risks may have impacts and outcomes that are currently extremely difficult to predict. Increased R&D expenses, lost sales opportunities due to reduced customer satisfaction and brand image, and delays in procurement, production, and distribution due to abnormal weather are among the potential impacts of these risks. These risks could have a material impact on the operating results and financial position of the SUBARU Group.

On the other hand, effective initiatives to address climate change could lead to opportunities to create new markets and employment and also use capital and energy more efficiently.

Main Risks Identified

Business Management in General

Reputational risk

(1) If SUBARU fails to implement adequate initiatives to achieve low-carbon/zero-carbon outcomes, its brand value could be harmed, which could affect the Company’s sales and recruiting ability. Capital costs could also rise, due to increased difficulty in obtaining financing from medium- and long-term investors.

Regulatory risk

(2) There is an argument that nationally determined contributions (NDCs) need to be expanded to be able to achieve the Paris Agreement’s “well below 2°C” target, and thus countries may revise their NDCs to set more stringent targets. Such revisions could have a significant impact on SUBARU’s business activities.

Acute physical risk

(3) As an impact of climate change, extreme torrential rain will frequently cause floods in various locations, which could pose risks of SUBARU’s operations being affected by disrupted supply of raw materials and submerged factories.

Products

Regulatory risk

(1) If SUBARU fails to meet fuel economy regulations imposed in Japan, the U.S., Europe, and China, the Company could incur additional costs or losses related to negative incentives, such as fines or non-penal fines for legal violation, and credit purchase for unmet standards. Also, some of our products could fail to satisfy certain fuel economy standards, resulting in restrained sales opportunities.

Market risk

(2) At present, it is difficult to predict technological progress and price optimization for electrification, which will likely cause a substantial gap with the real state of market needs. In such a situation, SUBARU could incur unnecessary and excessive R&D costs while facing a decline in customer satisfaction, resulting in unexpected losses and reduced sales opportunities as well as hampered advancement of the Company’s electrification efforts.

(3) SUBARU views electrification as a steady medium- to long-term trend, and also anticipates the possibility of its swift and sweeping penetration of the market at some stage. SUBARU could be unprepared for such prospect in terms of technology and timely product lineups, and thus suffer from a resultant loss of product sales opportunities.

Technology risk

(4) To promote electrification, it is crucial to ensure profitability for the entire product cycle ranging from procurement and use to disposal. Thus, it is essential to involve SUBARU’s upstream and downstream partners in exerting efforts toward this end. Failure to do this could render the Company unable to meet the profitability goal for the entire product life cycle.

Chronic physical risk

(5) There is a possibility that SUBARU might suffer from shortages of natural resources used for tires and metal resources, such as materials for automotive batteries, for electrification technologies.

Production Phase

Regulatory risk

(1) If SUBARU continues to use energy derived from fossil fuels, it could incur rising costs, due not only to geopolitical factors associated with petroleum and the like, but also to carbon taxes, emission quotas, and other government policies and regulations.

Technology risk

(2) If use of renewable energy does not grow as expected, SUBARU could face slower progress in achieving its Scope 1 and 2 emissions reduction goals.

Main Opportunities Identified

Market opportunity

(1) If SUBARU advances its efforts to make products more environmentally friendly as planned and global climate change mitigation/adaptation efforts progress adequately, the Company will be able to maintain its key markets while at the same time potentially expanding in markets receptive to its offer of “Enjoyment and Peace of Mind.”

(2) Through contributing to addressing climate change issues, SUBARU could increase its brand value, thereby enhancing its sales and recruiting ability. This could make it easier for the Company to obtain financing from investors, thereby lowering capital costs.

Energy-related opportunity

(3) Regarding energy use during the production phase, by transitioning to renewable energy while at the same time giving due consideration to cost-effectiveness, SUBARU could overcome the risk of being exposed to price fluctuations involved in energy derived from fossil fuels, thereby preventing future cost increases.

- Note:

- The risks and opportunities described above are based on past facts and currently available information, and may change significantly due to such factors as future economic trends and the business environment facing SUBARU. The opportunities described represent those for SUBARU’s products to contribute to climate change adaptation and do not anticipate climate change-related deterioration.

Examples of scenarios and their risks/measures

As an example measure, SUBARU has developed an electrification strategy that considers multiple scenarios, including one in which the percentage of EVs sold in the market increases significantly, as well as one in which the market penetration of EVs increases modestly. We are also advancing BCP* measures against water-related disaster risk for our business partners and against flooding during torrential rainfall. This action is in consideration of the risk of increasingly severe natural disasters due to a lack of progress in addressing climate change.

- *

- BCP: Business continuity plan

| Scenario | Example scenario risks of particular importance | Measures | |

|---|---|---|---|

| Penetration of BEVs | Products | Risk of limited product sales opportunities due to failure to meet certain fuel economy standards |

|

| Risk of market need diverging from electrification technology | |||

| Increasing severity of natural disasters | Business management | Risk of operations being affected by disrupted supply of raw materials and submerged factories as a result of frequent flooding in various locations from extreme torrential rain |

Taking measures against flooding by installing rainwater collection tanks and strengthening drainage capacity Organizing a system for restoration support activities in the event of a contingency at business partners and assessing the risk of water-related disasters |

Strategy

At this stage, it is difficult to foresee the future direction of electrification. Therefore, while keeping a close eye on the trends in regulations and the market, SUBARU is taking various actions based on the recognition that it is extremely important to ensure flexibility and expandability, using this concept to adapt to such changes flexibly and to expand at once when the direction of the shift becomes clear.

From a medium- to long-term perspective, we believe that BEVs will eventually become a core driver toward achieving carbon neutrality, but from 2025 to 2026, when the transition to BEVs is in its early stages, we will ensure flexibility in adapting to environmental changes through initiatives in each of the areas of development, products, and production.

Furthermore, for the upcoming diffusion (or expansion) phase for BEVs, we will need to harness the fruits of our work in "Monozukuri Innovation" and "Value Creation". At the Innovation Hub, which launched in January 2024, employees and business partners can gather and engage with each other without traditional boundaries to talk about various aspects of development and production (Obeya activities), and through collaboration with other companies, we are promoting activities to realize the aforementioned "Monozukuri Innovation" and "Value Creation."

Through these efforts, we will promote the "One SUBARU" approach, in which we develop highly dense connections between development, manufacturing, and the supply chain, as we aim for in-house development of BEVs that we expect to launch by the end of 2028 through leveraging the insights of our alliance. In addition, various knowledge gained in the process of promoting "Monozukuri Innovation" and "Value Creation" will be utilized to strengthen ICE products.

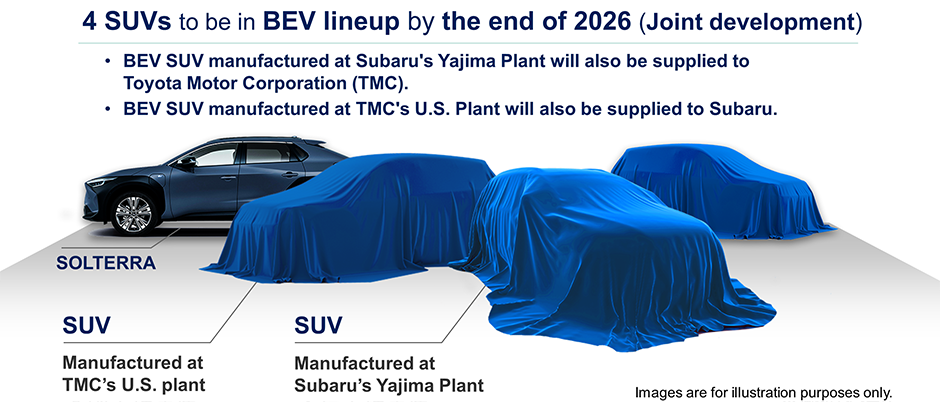

Battery EV Development

After consideration various options for the development of BEVs, including solely SUBARU-made BEVs and those developed through our alliance, we decided to jointly develop the four BEV models to be added to our lineup by the end of 2026 with Toyota Motor Corporation (hereinafter, “Toyota”) bringing together the knowledge and expertise of both companies.

Battery EV Production

Our jointly-developed BEVs produced at the Yajima Plant will also be supplied to Toyota. Meanwhile, BEVs produced at Toyota's U.S. plant will be supplied to SUBARU, giving SUBARU a lineup of BEVs produced in the U.S. Through joint development, mutual production, and mutual supply alongside Toyota, we will mitigate risks and ensure flexibility in development and production areas in these times when it is difficult to foresee the future.

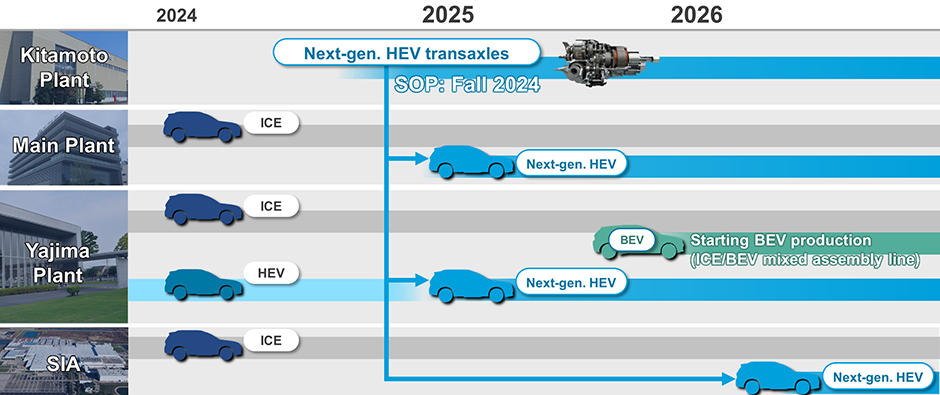

HEV Products and Production

In addition to the Forester, we will expand the rollout of the Next-generation e-BOXER, SUBARU's unique hybrid electric vehicle (HEV) with a horizontally-opposed engine based on the TOYOTA Hybrid System, to the Crosstrek as well. In the early stage of the shift to BEVs, HEVs will be extremely important, and strengthening HEV products will ensure product flexibility and expand customer choices. For the next Forester models, both the gasoline model and the next-generation e-BOXER model will not only be produced at our plants in Japan, but will also be produced at Subaru of Indiana Automotive, Inc., so that we can ensure flexibility within production in both Japan and the U.S.

Model Production Plan per Plant from 2025 to 2026

Production of transaxles, which will be a core unit of the next-generation e-BOXER, will begin at SUBARU’s upgraded Kitamoto Plant in the fall of 2024.

The next-generation e-BOXER will initially be installed in vehicles manufactured at our plants in Japan, with plans to eventually install it in vehicles manufactured in the U.S. as well. In addition, the BEVs produced at the Yajima Plant will be supplied to Toyota Motor Corporation, ensuring production flexibility adapted to demand.

Aim to Halve Development Days, Production Processes, and Number of Parts while Implementing Planned CO2 Emission Reduction Measures in Plants and Offices

SUBARU will strive to achieve world-leading monozukuri by cutting the development lead time in half, the configuration and number of parts in half, and the production process in half. In our current operations, each segmented function, such as product planning, design, and production, waits for the previous process to complete its work, and then passes the work on to the next process like a relay. Through our "Monozukuri Innovation" initiatives, we will make the process agile, which will lead to a 50% reduction in monozukuri time.

At the same time, by continuously advancing these initiatives, we will reduce the process and lead time for product development and production in existing domains and strengthen our ability to respond to domains experiencing non-linear transformation in this age of uncertainty.

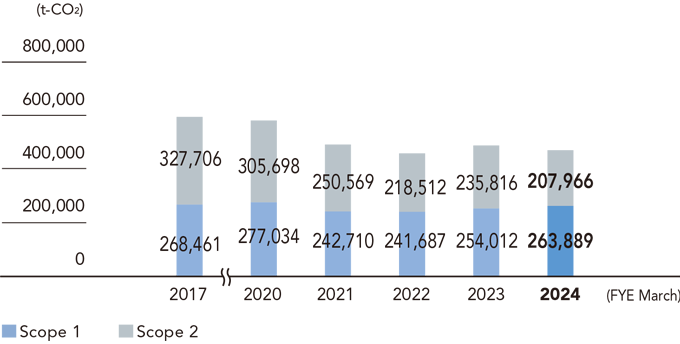

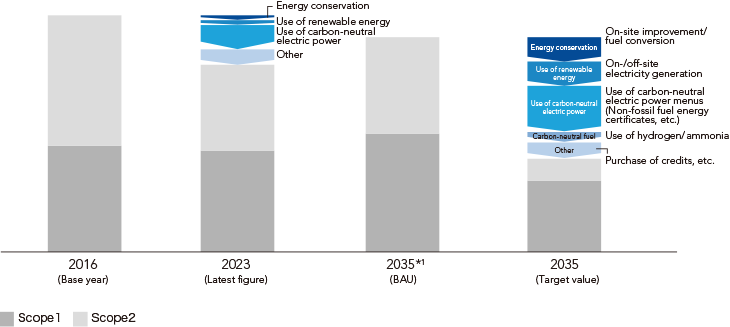

SUBARU aims to halve development lead times, the production process, and the configuration and number of parts, while also aiming to reduce CO2 emissions from plants and offices (Scope 1 and 2 emissions) by 60% in 2035 versus FYE March 2017 levels on a total volume basis. SUBARU will take actions toward energy self-sufficiency and efficiency and therefore accelerate the reduction of CO2 emissions through streamlining in a dual approach for both the manufacturing process and product structure.

The SUBARU Group will systematically implement measures to reduce Scope 1 and Scope 2 emissions by 2035, including energy-saving measures, the introduction of carbon-neutral fuel such as hydrogen and ammonia, and the use of in-house and purchased carbon-neutral power generation, with the aim of achieving its targets.

Illustration of Scope 1 and 2 Emission Reduction Measures and Impact up to 2035

- *1

- Assuming the electricity emission coefficient in Japan decreases to 0.25 t-CO2 per thousand kWh

FYE March 2024 Reduction Measures and Impact

| Measure | CO2 reduction impact (t-CO2) |

|---|---|

| Generation of renewable energy (solar power generation) | 4,445 |

| Purchase of carbon-neutral electricity | 51,388 |

| Introduction of high-efficiency air-conditioning systems | 2,000 |

| Replacement of Cogeneration Facilities | 3,712 |

| Energy conservation through information and communications technology (ICT)/IoT | 500 |

| Use of Green Power and Green Heat Certificates | 4,064 |

| Total | 66,109 |

Risk Management

The automotive industry is ushering in a major transformation, which only occurs once in a hundred years. The SUBARU Group, which operates businesses globally, is aiming to enhance the resilience of its management infrastructure by ensuring the sustainability of its businesses by quickly tackling changes in world affairs. At the same time, the Group must boost its measures to minimize its human, social, and economic losses. Amid this environment, it is essential to strategically conduct risk management throughout the Group to conduct business activities. We therefore believe it is important to create a SUBARU Group that has an infrastructure that is resilient to risk to enhance our corporate value. As the environment surrounding the SUBARU Group continues to experience disruptive and non-linear changes at an unprecedented pace, we are working to further strengthen our risk management, including the use of a new Risk Map formulated through management-level discussions that take into account external changes and the current environment, in addition to the important risks of each division, in order to more reliably achieve the New Management Policies.

To address climate change-related transition risks in policy and regulation, technology, markets, and other items, dedicated departments at SUBARU gather information from a wide range of sources and work to identify uncertain climate change-related risks from future projections. These transition risks are proposed and discussed during the Executive Meeting, and particularly significant matters are subject to deliberation within the Board of Directors before decisions are made.

The physical risks associated with climate change include flooding and other natural disasters. The Risk Management and Compliance Office plays a pivotal role in establishing regulations in response to these operational risks as part of the BCP system. During emergencies, the office centrally grasps Group-wide information, establishing a system to manage company-wide response.

Medium- to Long-term Goals (Long-term Vision and Milestones)

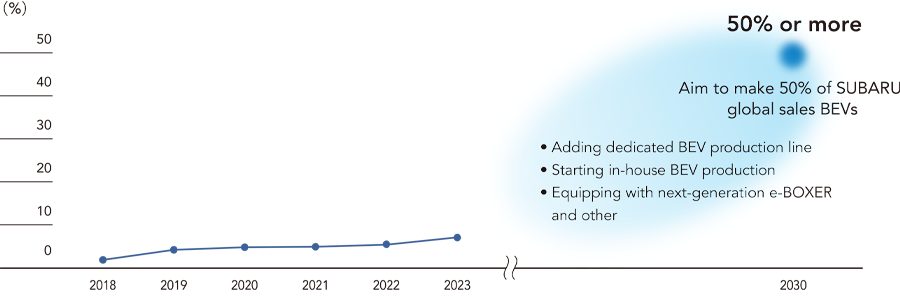

In order to contribute to a decarbonized society, SUBARU has set long-term goals (long-term vision) for 2050 and medium-term goals (milestones) regarding products (Scope 3) and plants and offices (Scope 1 and 2). These medium-term goals are reviewed as necessary according to the business environment, which is experiencing rapid, disruptive changes. In 2023, the medium-term goal for plants and offices (Scope 1 and 2) has been set as reducing CO2 emissions by 60% in FYE March 2036 versus FYE March 2017. The medium-term goal for products (Scope 3) has been re-established as aiming to make BEVs 50% of all automobiles sold in 2030.

SUBARU is investigating compliance with relevant policies including the fuel efficiency regulations of the countries it serves. We formulate our own scenarios and plans for achieving our medium- to long-term goals based on policy trends and scenario-specific information published by the International Energy Agency and others.

| Category | Target Year | Goal |

|---|---|---|

| Products (Scope 3) |

2050 | Reduce average well-to-wheel CO2 emissions from new vehicles (in operation) by 90% or more compared to 2010 levels |

| Early 2030s | Apply electrification technologies to all SUBARU vehicles produced and sold worldwide | |

| 2030 | Aim for 50% of global sales to be BEVs | |

| Plants and offices (Scope 1 and 2) |

FYE March 2051 | Achieve carbon neutrality |

| FYE March 2026 | Reduce CO2 emissions by 60% compared with FYE March 2017 (total volume basis) |

Initiatives

For FYE March 2024, SUBARU has reported a total of 39,914 thousand t-CO2 of supply chain greenhouse gas emissions (Scope 1, 2, and 3). Out of the total amount, 98% is related to Scope 3, the majority of which stems from the use of sold products. Although the Group's direct CO2 emissions (Scope 1 and 2) constitute only a marginal portion of the total (including Scope 3), we are making proactive efforts to diminish direct emissions, which we believe will encourage the entire SUBARU value chain to work as a team and in greater earnest.

- Scope 1: Direct emissions of greenhouse gases from a company’s own facilities.

- Scope 2: Indirect emissions of greenhouse gases from the use of purchased or acquired electricity, heat, and/or steam supplied by another company.

- Scope 3: All indirect emissions other than Scope 1 and 2 emissions, including those arising from the procurement of raw materials, transport, product use, and the disposal process, as well as arising from employee commuting, business travel, etc.

CO2 Emissions (Scope 3)

| Category | Greenhouse Gas Emissions(t-CO2) | |||||

|---|---|---|---|---|---|---|

| FYE March 2020 | FYE March 2021 | FYE March 2022 | FYE March 2023 | FYE March 2024 | ||

| 1 | Purchased goods and services | 6,181,341 | 5,136,697 | 4,339,656 | 5,018,874 | 5,861,321 |

| 2 | Capital goods | 413,287 | 282,713 | 260,566 | 402,915 | 549,384 |

| 3 | Fuel- and energy-related activities not included in Scope 1 or Scope 2 | 103,772 | 91,851 | 89,627 | 95,352 | 54,958 |

| 4 | Transport and delivery (upstream) | 737,817 | 601,167 | 506,604 | 426,929 | 500,914 |

| 5 | Waste generated in operations | 32,095 | 26,446 | 24,888 | 28,733 | 8,608 |

| 6 | Business travel | 4,554 | 4,689 | 4,798 | 4,878 | 4,900 |

| 7 | Employee commuting | 13,835 | 14,245 | 14,576 | 14,818 | 14,885 |

| 8 | Leased assets (upstream) | N/A | N/A | N/A | N/A | N/A |

| 9 | Transportation, distribution, and sales (downstream) | 6,049 | 3,893 | 4,750 | 4,043 | 3,521 |

| 10 | Processing of sold products | N/A | N/A | N/A | N/A | N/A |

| 11 | Use of sold products | 34,029,045 | 27,455,302 | 23,102,609 | 27,453,385 | 31,864,033 |

| 12 | End-of-life treatment of sold products | 582,263 | 484,440 | 413,368 | 485,555 | 577,694 |

| 13 | Leased assets (downstream) | 2,463 | 1,998 | 2,065 | 1,984 | 1,562 |

| 14 | Franchises | N/A | N/A | N/A | N/A | N/A |

| 15 | Investments | N/A | N/A | N/A | N/A | N/A |

- Source:

-

The calculation method for SUBARU Scope 3 emissions has been revised in reference to the Basic Guidelines on Accounting for Greenhouse Gas Emissions throughout the Supply Chain Ver. 2.3 (December 2017) by the Ministry of the Environment and the Ministry of Economy, Trade and Industry; the Emissions Unit Value Database Ver. 3.0 by the Ministry of the Environment Database of emissions unit values; and SUBARU’s life-cycle assessment (LCA) calculation standards.

Retroactive correction has been made to data from previous years due to revisions to the calculation method for “1 Purchased goods and services” and “12 End-of-life treatment of sold products.”

Life-cycle Assessment

In order to contribute to the realization of a decarbonized society through the reduction of CO2 emissions throughout the life cycle of our business activities, SUBARU has designated departments in charge of the five areas of “product use,” “materials and components,” “transportation,” “disposal,” and “manufacturing.” We now also hold monthly CN Promotion Meetings, bringing together representatives from the relevant departments in each area. In these CN Promotion Meetings, members share information from each area, formulate a master plan from a medium- to long-term perspective, and visualize the transition of emissions in each area in the interest of achieving carbon neutrality by 2050.

Approach to CO2 emissions reduction from an LCA perspective

SUBARU conducts LCA* to evaluate CO2 emissions during the entire life cycle of automobiles. We will quantify the environmental impact of automobiles and proactively develop automobiles taking into account the need for decarbonization from the design stage. When compared to the previous models, the current Impreza achieved a 2.4% reduction in CO2 emissions, and the current Forester achieved an 8.7% reduction.

- *

- Life-cycle assessment (LCA) is an environmental impact assessment method that comprehensively evaluates environmental load at every stage of the life cycle of products and services from raw material procurement to production, use, disposal, and recycling. For SUBARU, assessments are for cars built for the Japanese market.

Product Initiatives

The percentage of SUBARU’s EVs as a share of global sales (retail sales basis) in FYE March 2024 was 7.8%, and the percentage of BEVs was 1.5%. We will grow our earnings base in the BEV era by strengthening our supply capacity for EVs, including the start of in-house BEV production in the mid-2020s in conjunction with the reorganization of our domestic production system, the launch of the next-generation e-BOXER, and the addition of dedicated BEV production lines in the late 2020s. As we do this, we will work to ensure a high level of financial soundness, taking actions in a sustainable structure toward our stated goal of aiming for 50% of SUBARU global sales to be BEVs in 2030.

As an aircraft manufacturer, SUBARU has been developing technologies for decarbonization to realize a sustainable society, and in March 2024, SUBARU successfully conducted test flights using sustainable aviation fuel (SAF*1) in a helicopter.

- *1

- Sustainable aviation fuel is produced from resources such as plants and waste oil. Plants, which are the main raw material, absorb carbon dioxide from the atmosphere during photosynthesis, thus achieving a balance between absorption and emission, offering reduction in greenhouse gas emissions compared to conventional fossil fuel-based aviation fuels.

Results and future plan of percentage of EVs sold (retail sales basis)

Efforts to Reduce CO2 Emissions for New Models

SUBARU is naturally working to improve the fuel efficiency of gasoline-powered vehicles while turning its attention to expanding its lineup of EV models, especially the development and supply of BEVs. We believe it will be especially important to steadily promote the expansion of the above initiatives in order to reduce the amount of CO2 emitted from automobiles.

Battery Electric Vehicles (BEVs)

In May 2022, SUBARU launched the Solterra as another step toward the era of the electric car. Its first global BEV, the Solterra is designed to achieve coexistence with nature. It utilizes the e-SUBARU Global Platform, a dedicated EV platform we jointly developed with Toyota Motor Corporation (“Toyota”), as well as the AWD technology we have developed for many years and Toyota’s outstanding electrification technology, thus bringing together the strengths of both companies and efficiently leveraging our development investments. In addition to the Solterra, we plan to launch three new BEVs to the SUV category by the end of 2026. Of these, one model will be produced at SUBARU's Yajima Plant and supplied to Toyota Motor Corporation as well. Like with our existing vehicles, we will bring SUVs featuring the unique appeal of SUBARU’s BEVs to Japan, the U.S. and Canada, Europe, China, and other markets, aiming to further strengthen the value we offer with the goal of being a brand that is “different” from others. We are also planning to add four more models to our BEV lineup by the end of 2028.

At SUBARU, we will continue to help protect the environment as we consider practical functions and customer preferences in enhancing our lineup in the markets we serve with environmentally friendly vehicles that are unique to SUBARU.

Hybrid Electric Vehicles (HEVs)

SUBARU has been increasing the number of vehicles equipped with its mild hybrid e-BOXER engine that combines a horizontally-opposed engine and electrification technology, and to reduce CO2 emissions has implemented initiatives such as creating its own PHEV using HEV expertise from Toyota. In addition, looking ahead to 2025, we will begin next-generation e-BOXER production that incorporates THS*2 technology to deliver vehicles that feature the SUBARU Difference while offering high-level environmental performance. For the next-generation e-BOXER, we have evolved the model from a parallel system for transmitting engine and motor power in parallel to a more efficient series-parallel system. In addition, the power control unit is mounted on top of the engine to ensure a large fuel tank capacity and a competitive cruising range. This next-generation e-BOXER will be installed in the Crosstrek and Forester. By steadily expanding our product lineup of EVs, we will help reduce CO2 emissions for new models.

- *2

- THS: TOYOTA Hybrid System

Gasoline-Powered Vehicles

We will continue to meet demand for conventional gasoline-powered vehicles from customers. HEVs, which we are expanding to include more models, are made by combining gasoline engines with electrification technology, and engines need further technological improvements to boost fuel efficiency. The 1.8-liter BOXER DIT*3 combines the unique driving pleasure of a SUBARU with outstanding environmental performance. Installed in the Levorg, Forester, Outback, and Layback models, it is a next-generation BOXER engine with a turbo system that generates high torque at low RPM. Its lean combustion technology produces more energy with less fuel. Combined with the expanded Lineartronic shift range, this engine offers even more powerful acceleration off the line and superb fuel efficiency when cruising at high speed. In addition, SUBARU is continuing to pursue the potential offered by engines in the era of carbon neutrality by participating in races with vehicles that use carbon-neutral fuel, as well as participating in the Research Association of Biomass Innovation for Next Generation Automobile Fuels.

- *3

- Direct injection turbo

TOPICS

Research Association of Biomass Innovation for Next Generation Automobile Fuels

SUBARU, together with ENEOS Corporation, Suzuki Motor Corporation, Daihatsu Motor Co., Ltd., Toyota Motor Corporation, and Toyota Tsusho Corporation, established the Research Association of Biomass Innovation for Next Generation Automobile Fuels to research efficiency improvements in processes to produce fuel. Currently, seven companies, including Mazda Motor Corporation, are participating in this association to advance technological research on the use of biomass and efficient production of bioethanol fuel for automobiles in order to realize a carbon-neutral society.

TOPICS

Conducted a Helicopter Test Flight Using Sustainable Aviation Fuel (SAF)

In March 2024, SUBARU successfully conducted a test flight using SAF in a Group-owned helicopter. As an aircraft manufacturer, Subaru will continue to develop decarbonization technologies to contribute to the realization of a sustainable society.

Site Initiatives

SUBARU is reducing its CO2 emissions by using renewable energy and upgrading to highly efficient machinery and equipment with the aim of achieving carbon neutrality by 2050. Scope 1 and 2 emissions in FYE March 2024 amounted to 471,854 tons (market-based), representing a decrease of 18,000 tons from the previous year and a 20.9% reduction compared to FYE March 2017 (The location-based Scope 1 and 2 emissions for FYE March 2024 were 545,917 tons.).

Renewable energy in FYE March 2024 accounted for 7.2% of the energy consumption of the entire SUBARU Group and 22.5% of its total electricity consumption. All of the electricity purchased at the Gunma Main Plant, Utsunomiya South Plant and 2nd South Plant, the Ebisu Subaru Building, and the SUBARU Academy is carbon-neutral electric power. In addition, unit CO2 emissions improved by 24% year on year due to greater energy efficiency. Toward the medium-term goals for FYE March 2036, the SUBARU Group will continue implementing energy-saving measures along with other initiatives, such as in-house generation or purchase of carbon-neutral electric power and introduction of hydrogen, ammonia, and other carbon-neutral fuels, as part of systematic Scope 1 and 2 emissions reduction. In addition, Subaru Kohsan Co., Ltd. sells solar generated from solar power generation facilities in Gunma and Shiga prefectures.

CO2 Emissions by Organization

CO2 Emissions by Scope

Scope:

- SUBARU:

- SUBARU CORPORATION

- Domestic Group companies:

- 52 domestic consolidated subsidiaries (including 33 SUBARU domestic dealerships that are consolidated subsidiaries)

- Overseas Group companies:

- Subaru of Indiana Automotive, Inc., Subaru of America, Inc., Subaru Canada, Inc., Subaru Research & Development, Inc.

SUBARU calculates CO2 emissions based on the Act on Promotion of Global Warming Countermeasures. However, for emissions coefficients for electricity used at Group companies outside Japan, we use the most recent country-specific CO2 emission intensities for all power sources published annually by the International Energy Agency (IEA).

The scope of data for domestic Group companies is that for consolidated subsidiaries, and the confirmation for Scope 1 and 2 emissions is 99% (based on proportion of workforce). In addition, errors were found in the aggregated data for FYE March 2023, and corrections were made.

Energy use

Scope:

- SUBARU:

- SUBARU CORPORATION

- Domestic Group companies:

- 52 domestic consolidated subsidiaries (including 33 SUBARU domestic dealerships that are consolidated subsidiaries)

- Overseas Group companies:

- Subaru of Indiana Automotive, Inc., Subaru of America, Inc., Subaru Canada, Inc., Subaru Research & Development, Inc.

SUBARU calculates energy consumption (GJ) based on the Act on the Rational Use of Energy.

In addition, errors were found in the aggregated data for FYE March 2023, and corrections were made.

Gunma Plant

Purchase of Carbon-Neutral Electricity (Gunma Main Plant, Oizumi Plant)

The Gunma Main Plant had been purchasing a portion of its electricity through the Aqua Premium rate plan specifically for sales of hydropower, but switched to the Power Gunma Hydropower plan in November 2020. All of its electricity is now derived from hydropower, which reduced CO2 emissions by approximately 24,500 tons in FYE March 2024.

We also reduced CO2 emissions by 8,394 tons by using non-fossil fuel certificates for 21,524 MWh of electricity at the Oizumi Plant of Gunma Manufacturing Co., Ltd. purchased in FYE March 2024, comprising 16% of purchased electricity.

Introduction of High-efficiency Air-conditioning Systems (Gunma Yajima Plant)

We replaced the aging cooling water supply system of the 3rd Paint Plant. In April 2022, the plant, which had previously used an absorption chiller with city gas and hot water from the cogeneration facility as the heat source, introduced a centrifugal chiller with an electrically operated heat pump. This has essentially eliminated the use of city gas by updating the heat source of the absorption refrigerator to only hot water from the cogeneration facility.

In 2018, the 5th Paint Plant also introduced a high-efficiency heat source system, centered on heat pumps for cold and hot water supply to reduce CO2 emissions. SUBARU plans to roll out this system to the new Oizumi Plant, which is scheduled for future construction.

Replacement of Cogeneration Facilities

At the Gunma Plant, we operate cogeneration facilities at the Main Plant, Oizumi Plant, and Yajima Plant to promote efficient energy use. In FYE March 2024, the Oizumi Plant continues operation after an update in the previous fiscal year of its aging facilities, which were updated after 16 years of operation. For the replacement, we selected equipment with specifications that make a greater contribution to energy savings in light of the most recent energy consumption profile. Compared to the previous facilities, the new facilities offer annual emissions reduction of 3,712 t-CO2, according to their specifications.

Introduction of solar power generation

We have introduced solar power generation facilities at the Gunma Main Plant and Oizumi Plant. These facilities achieved a CO2 emissions reduction of approximately 2,732 t-CO2 in FYE March 2024. Solar power generation equipment will be incorporated into new building rooftops from the specification stage, and we are considering expanding this to existing buildings and parking lots over time.

At the Yajima Plant, we also installed solar power generation equipment with an output of 850 kW in the No. 3 final vehicle inspection wing in September 2023, in addition to the installation of similar facilities in 2022, the multistory parking garage and No. 5 final vehicle inspection wing, resulting in an overall reduction of 591 t-CO2 of emissions at the plant overall.

Aerospace Company (Utsunomiya Plant and Handa Plant)

Purchase of carbon-neutral electricity

(Tochigi Furusato Denki Program for regional production and consumption)

In FYE March 2019, SUBARU’s Aerospace Company adopted the Tochigi Furusato Denki program*1 to provide electricity to its Utsunomiya South and 2nd South Plants. The program offers electricity from hydropower generation projects owned by Tochigi Prefecture, and represents Japan’s first-ever power supply program themed on the “local production for local consumption” concept.

The above program enables the two plants to reduce emissions by an average of 4,000-plus t-CO2 per year. This program also includes a scheme to spend part of the funds from bill payment, including from SUBARU, on environmental conservation projects promoted in Tochigi Prefecture.

- *1

- Electricity service program co-hosted by the Tochigi Public Enterprise Bureau and TEPCO Energy Partner, Inc. Supplies electricity generated by eight hydroelectric power stations run by the Tochigi prefectural government. Hydropower users can claim to be emitting no CO2 from using the electricity, on the grounds of its CO2-free generation process.

Acquisition of Nearly ZEB Certification at the Main Administration Building

The Aerospace Company's Main Administration Building, built at the Utsunomiya Plant and with operations started in September 2023, is the first building in the SUBARU Group to receive Nearly ZEB*2 certification under the Building-Housing Energy-efficiency Labeling System (BELS) in Japan. In addition, the solar power generation facilities installed on the roof of the Main Administration Building reduces CO2 emissions by approximately 130 tons per year.

- *2

- Nearly ZEB is a building that achieves at least a 75% reduction in primary energy consumption compared to a reference building and is very close to achieving Net Zero Energy Building certification.

Replacement of Cogeneration Facilities

In addition to reducing CO2 emissions, since March 2021 the cogeneration system has enhanced community and employee safety with its blackout start function that can initiate power generation if the power grid goes down for an extended period.

IoT Enables Stable Supply of Factory Air and Improved Energy Efficiency

SUBARU is moving forward with Digital Transformation (DX) driven by ICT and the IoT beginning the systemization of air factory analysis, data analysis, and the introduction of countermeasures in November 2019. We have implemented three measures: investigating and repairing air leaks, restricting air supply, and improving operating efficiency. We expect energy savings to reduce CO2 emissions by 500 tons per year.

Improve Compressor Operating Efficiency

Tokyo Office

The Tokyo Office is in Mitaka City, Tokyo. It is subject to the Tokyo Cap-and-Trade Program for large facilities as per the Tokyo Metropolitan Environmental Security Ordinance. The Tokyo Office is therefore reducing CO2 emissions with two priority initiatives: promoting energy conservation by improving facilities and by proactively adopting energy-saving equipment.

We are also working to utilize renewable energy, and have installed rooftop solar power generation equipment (total rated output of 140 kW) at our facilities. In FYE March 2024, the facilities generated 199 MWh of electricity for use in-house, achieving a CO2 emissions reduction of 37 t-CO2. In addition, we began to utilize Japan's Green Power Certification System in 2019, and in FYE March 2024 we purchased certificates equivalent to 8,535 MWh of electric power, equivalent to 3,329 t-CO2 of emissions, during the fiscal year. The Main Building in Tokyo Office, completed in September 2022, is designed to be environmentally friendly, employing energy-saving technologies such as solar power generation, LED lighting throughout the building, shielded and insulated glass, and building materials with heat shielding and high thermal insulation. In addition, creating cold mix asphalt during construction has contributed to a 38.5 t-CO2 reduction in emissions. We are also progressively converting fixtures in existing buildings to LED lighting.

Offices

Head Office (Ebisu Subaru Building) and SUBARU Training Center

Since FYE March 2022, we have switched to contract options with zero electricity emission coefficients, and we make use of the Green Heat Certificate system. In FYE March 2024, we achieved net-zero emissions for the office, carbon-neutralizing emissions equivalent to 881 t-CO2. In addition, from April 2023, all electricity used in the entire Ebisu Subaru Building has been switched to sources with zero CO2 emissions.

SUBARU Accessory Center

In FYE March 2024, the use of 1,153 MWh of electric power generated by solar power facilities installed in March 2020 resulted in a yearly CO2 emissions reduction of 450 t-CO2.

SUBARU Research and Experiment Center

The SUBARU Research and Experiment Center installed solar power generation equipment in FYE March 2018, and generated 82 MWh in FYE March 2024, resulting in a yearly CO2 emissions reduction of 32 t-CO2.

Group Companies in Japan

Fuji Machinery Co., Ltd.

In FYE March 2024, we reduced annual CO2 emissions by approximately 1,016 t-CO2 by using non-fossil certificates for a total of 2,605 MWh, comprising 20% of purchased electricity at the head office/plant and 100% at the Isesaki Plant.

The Oizumi Plant of Fuji Machinery Co., Ltd. also installed solar power generation equipment in FYE March 2018. In FYE March 2024, this equipment generated 38.5 MWh of electricity, resulting in an annual CO2 emissions reduction of 15 t-CO2.

Ichitan Co., Ltd.

Ichitan Co., Ltd. has been achieving annual emissions reductions of 3,400 t-CO2 by purchasing CO2-free electricity. In addition, we introduced solar power generation in September 2023 and began generating our own power. Information on power generation and other data is displayed on a monitor in the lobby of the company entrance, offering utilization status at a glance. In order to promote the transition from gasoline-powered to electric vehicles for company cars, the Kyushu Plant has introduced the Solterra BEV and is working to reduce CO2 emissions.

Subaru Kohsan Co., Ltd.

Subaru Kohsan Co., Ltd. entered the business of marketing electricity from solar power generation operations. It sells electricity generated from solar power equipment with a rated output of 420 kW (equivalent to 100 detached houses) installed in Kiryu, Gunma Prefecture and equipment with a rated output of 1,470 kW (equivalent to 350 detached houses) installed in Konan, Shiga Prefecture. The company has also promoted the use of renewable energy by installing solar power generation facilities at its Ota S Building and the new wing of its Higashi-Nagaoka company dormitory.

Subaru Kohsan Co., Ltd. has been certified as an excellent operator with respect to energy conservation (Class S) for five consecutive years since FYE March 2020 in accordance with the Act on the Rational Use of Energy. This evaluation is given to excellent operators that have met the five-year average per-unit emission reduction target of 1% or more in electricity and gas consumption.

Overseas Group Companies

Subaru of Indiana Automotive, Inc.

Subaru of Indiana Automotive, Inc. is implementing CO2 reduction initiatives in its production processes and Technical Training Center.

In the production process, we are implementing various measures aimed at reducing energy consumption, which include upgrading to LED lights, and installing control valves in the air conditioning systems of air handling units (AHUs) and makeup air units (MAUs).

In addition, at the Technical Training Center, we took measures such as installing solar power generation equipment while upgrading to LED lighting for all indoor lighting and introducing motion sensors.

Sales Initiatives

Dealerships

Dealerships in Japan, like the SUBARU Group, have set the goal of reducing CO2 emissions by 60% from the FYE March 2017 level by FYE March 2036, and are progressively purchasing carbon-neutral electricity. By FYE March 2024, this conversion has progressed to approximately 50% of electric power consumption, and we intend to further increase the ratio in the future.

Subaru of America, Inc.

Subaru of America, Inc.’s headquarters and National Service Training Center have acquired silver LEED certification,* which is higher than standard certification. In 2021, the company enhanced energy efficiency by installing automated equipment and comprehensive air conditioning systems at its headquarters building and National Service Training Center.

In addition, at the headquarters building, the company utilizes 100% renewable energy and has upgraded to LED lighting. In 2021, the headquarters lobby was designed to efficiently incorporate natural light, thereby reducing the electricity consumption for lighting.

- *

- Leadership in Energy and Environmental Design (LEED) certification is a green building certification system developed and operated by the U.S. Green Building Council (USGBC). It provides objective environmental performance data on buildings through evaluation of energy conservation and environmental impact reduction abilities for a range of project stages from overall planning and design to construction, management, and maintenance. Acquisition of the certification is becoming popular in the U.S. and in other countries.

Subaru Canada, Inc.

The building that houses Scott Subaru, a retailer in Canada, is designed for high energy efficiency, which includes eliminating the need for heating and cooling facilities. It has received certification as a “passive house,” or energy-efficient building.

Logistics Initiatives

SUBARU is collaborating across the entire Group, including with logistics companies, dealerships, as well as with other automotive industry players to reduce CO2 emissions in logistics operations by an annual 1% through increased transport efficiency for finished vehicles and export parts.

In FYE March 2024, all logistics-related departments within SUBARU gathered together to introduce their reduction activities, creating a forum for horizontally sharing and encouraging best practices. In addition, SUBARU believes that strengthening its supply chain will lead to achieving carbon neutrality by 2050, and we will continue efforts to increase the accuracy of CO2 emissions calculations and expanding their calculation scope, in addition to our reduction activities.

SUBARU’s logistics system

Transport of Finished Vehicles

SUBARU is establishing optimal standard routes for finished vehicles, flexibly accommodating shipping of a wide range of vehicle types and sizes (particularly large cars), improving loading efficiency, and promoting modal shift.*1 We also request that our logistics partners minimize the environmental impact of their transport operations, taking actions such as practicing eco-conscious driving by installing digital tachographs*2 and dash cams, as well as improving fuel efficiency by fitting aerodynamic panels and other devices.

As a result of expanded efforts for consolidated and standardized transportation routes, per unit CO2 emissions from transportation of SUBARU vehicles in FYE March 2024 declined 25.7% from the FYE March 2007 level, against the target of a 17% reduction from the base year. We will continue with our efforts to pursue further reductions.

- *1

- For cargo transportation, switching transportation modes from trucks to those imposing less environmental burden, such as railway and seaborne systems.

- *2

- Fitted to a vehicle to automatically record its journey information, including driving time and speed, and store the information in the installed recording medium, such as a memory card. The device is employed broadly by industries involving the commercial operation of vehicles as a tool for driving management. As the system can present clear data of recorded events, including sudden acceleration and deceleration, fuel-wasting engine idling, and dangerous driving, it is expected to help drivers increase their awareness of safe driving and fuel economy.

Export Parts

In the transport of parts for overseas SUBARU vehicle production, we are making efforts to improve the container fill rate through measures such as utilizing unused upper space in high cube containers, improving packing modes, and employing lighter-weight packaging materials. As a result, we achieved a fill rate of 98% in FYE March 2024. We will continue to actively work toward reducing CO2 emissions through other initiatives such as round use*5 to streamline container transportation, utilization of inland container depots*6, and the reuse of import containers used by other companies in the Gunma area.

- *3

- Using import containers for export instead of returning them empty to port, thereby reducing the transport of empty containers from ports.

- *4

- Depot located inland for consolidation of container cargo.

Parts and Accessories

- Joint distribution initiative with Toyota Mobility Parts Co., Ltd.

To resolve complexities and inefficiencies in parts of our transport system, we began joint distribution of maintenance parts with Toyota Mobility Parts Co., Ltd. in FYE March 2021. As of the end of FYE March 2024, we had started joint distribution to 12 dealerships (26 locations and sales partners in various regions). We aim to work toward joint distribution in other regions going forward.

By switching to joint distribution, we have in the case of some dealerships achieved a reduction of lead time by one day and a cut in transport costs of approximately 25%. - Switch to forklift trucks with electric drive option

The Accessory Center in Gunma is making a phased switch from liquefied petroleum gas (LPG)-operated forklift trucks to models that can be operated electrically. We will also equip the electric forklift trucks to make them available for use as storage batteries in the event of a disaster or power outage so that they can be used in times of emergency for instance to maintain telecommunications functions.

Subaru of America, Inc.

The company is promoting the use of rail to reduce CO2 emissions in the distribution process. We are also working to reduce emissions from marine transportation to dealerships in Alaska through the use of LNG. These efforts have resulted in a 25% reduction in CO2, a 95% reduction in NOx, and a 99% reduction in SOx. In 2023, we reduced transportation-related emissions by about 50% to 80% depending on the product. In addition, we are working to achieve sustainability in our supply chain by reducing greenhouse gas (GHG) emissions by up to 21% through LNG vessels operated by our shipping partners, and by preparing a system that exceeds the 2030 emissions standards of the International Maritime Organization.

Procurement Initiatives

We have set out a code of conduct that requires supplier selection and management mechanisms relating to climate change issues, and share the code with our suppliers, asking them to take appropriate actions when providing orientation sessions.

By encouraging business partners to obtain ISO 14001 certification, we are working to prevent environmental accidents and mismanagement events in the supply chain and reduce the risk of infringement of environmental laws and regulations.

In addition, we request that business partners cooperate in decarbonization during our procurement policy briefings. We will share our reduction targets for FYE March 2025 with our suppliers and spread awareness of working in unison to achieve these.

Other Climate Change Initiatives

Carbon Pricing

Emissions Trading Systems

As businesses operating in the jurisdictions of the Tokyo metropolitan and Saitama prefectural governments, our Tokyo Office, Kitamoto Plant, and Stellar Town Omiya are covered by the Tokyo Metropolitan Environmental Security Ordinance, which promotes greenhouse gas reduction and emissions trading for large businesses, and the Saitama Prefecture regulation on target-based emissions trading. Our business sites are responding through compliance with the relevant emissions trading systems.

In addition, SUBARU has endorsed the GX League Basic Concept announced by Japan’s Ministry of Economy, Trade and Industry. In line with this endorsement, we will participate in the GX League Emissions Trading Scheme (GX-ETS) from 2024.

Internal Carbon Pricing

SUBARU introduced internal carbon pricing in FYE March 2023. In the internal consultative plan on capital expenditures at business sites, the monetary value of the CO2 reduction accompanying the introduction of the relevant facilities is set at 6,000 yen/ton. By accounting for CO2 reduction impact in terms of its cost reduction impact, we ensure its inclusion as a factor in assessing capital expenditures. The introduction of internal carbon pricing, which comes under the category of shadow pricing, is intended not only to raise awareness of CO2 reduction among facility managers but also to promote investment in facilities with a high CO2 reduction impact.

External Partnerships

SUBARU is tackling the climate change challenge through partnerships with suppliers, customers, and industry groups.

Alliance with Toyota

SUBARU and Toyota have agreed to jointly develop EV platforms and vehicles applying SUBARU’s AWD technologies and Toyota’s electrification technologies. This agreement is designed to enable the two automakers to multiply their technical strengths with the goal of creating attractive EV products. As a dedicated BEV platform, they have jointly developed the e-SUBARU Global Platform.

Industry Groups

SUBARU is a member of the climate change committee of Japan Automobile Manufacturers Association, Inc. (JAMA). Also, the President and Executive Vice Presidents are JAMA directors responsible for the body’s executive decision making, and decisions made by JAMA are reflected in SUBARU’s management.

Declaration of Support for the TCFD Recommendations

SUBARU recognizes that climate change is one of the most pressing global issues, and has been working to disclose information on climate change. Accordingly, we have declared support for the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). For more information on SUBARU’s disclosure of the TCFD’s recommended items, please see our TCFD Content Index (https://www.subaru.co.jp/en/csr/tcfd/).

TOPICS

A Three-Company Commitment to Develop New Engines for the Electrification Era

SUBARU, along with Toyota Motor Corporation and Mazda Motor Corporation, have each committed to developing new engines tailored to electrification and the pursuit of carbon neutrality. With these engines, each of the three companies will aim to optimize integration with motors, batteries, and other electric drive units. While transforming vehicle packaging with more compact engines, these efforts will also decarbonize internal combustion engines by making them compatible with various carbon-neutral fuels*.

- *

- Fuels with net zero CO2 emissions into the atmosphere across their lifecycle, from manufacture to use. These include e-fuel, made from hydrogen and carbon dioxide, and biofuels derived from biomass (plants, etc.).